Eco-setting Spandex *(The Developing Product)

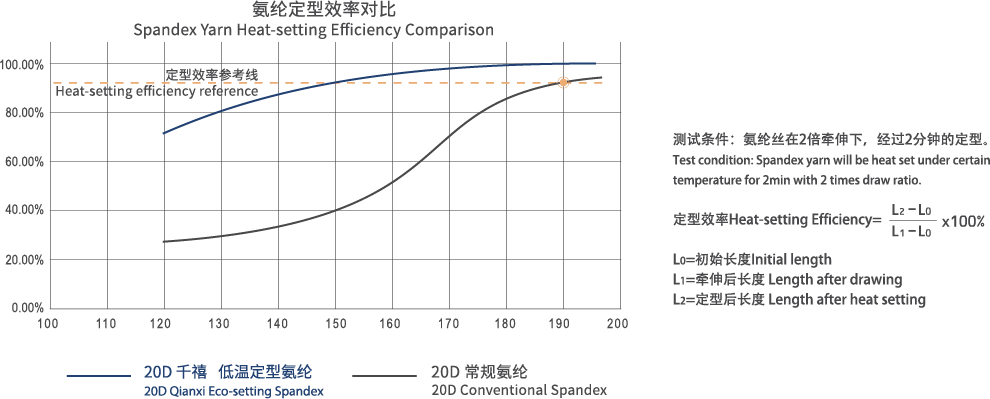

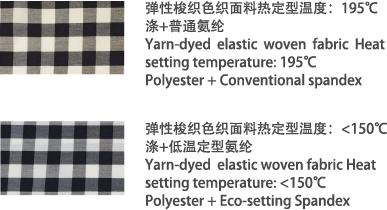

With high heat setting efficiency, the heat setting temperature of its fabric can be low to 130¡æ. Suitable for combining with heat sensitive fibers for elastic fabric development. Also it helps to prevent the sublimating problems of disperse dyes under high heat setting temperature and color contaminate, which can increase the pattern clarity of polyester yarn-dyed elastic fabric. Compared with melt-spining spandex, eco-setting spandex remains adequate elasticity and has stable performance and allows wider range of heat setting temperature.

High heat setting efficiency

Stable performance

Adequate easticity

Saving energy consumption

Allow winder range of heat setting temperature

1.Suitable for fibers that are sensitive to high heat setting temperature.(e.g.PP fiber, eco-friendly PLA fiber)

2.Suitable for high-grade polyester yarn-dyed elastic fabric.

Huafon Chemical Co., Ltd.

Add£ºNo.1788, Development Road, Ruian Economic Development Zone, Ruian, Wenzhou, Zhejiang

- Tel£º0577-65159999

- Fax£º0577-65537858

- E-mail£ºspandex@huafeng.com

- P.C.£º325200

Product and Service

- Qianxi Spandex

- Differentiated Spandex

- The Developing Product

- R&D Strength

- After-sale Service

- Hangtag Application